Accueil » Our offer

Our offer

Discover our offer

As a specialist in screw press technology, we provide our customers with a global response to their needs and according to their operating constraints.

Supply of equipment

We provide standard equipment that we adapt to each project. From a set of specifications or to be completed, our design office selects the most suitable model.

Engineering/Process

Adequatec places great importance on the quality of its process. Each sludge is unique and requires specific conditioning. Therefore, our flocculators are sized according to the rules of the art in terms of residence time and mixing energy. We also know how to integrate our dewatering units in a global project of implementation and by adapting to the existing works.

After Sales/Maintenance

With a return of experience most on the screw presses (15 years) the ergonomics of our machines and workshops were optimized for easy and ultra fast after-sales service in situ. On the ADEQUAPRESS, we recommend an annual control visit as well as a maintenance visit every 3 to 5 years depending on the time and the operating conditions of the unit.

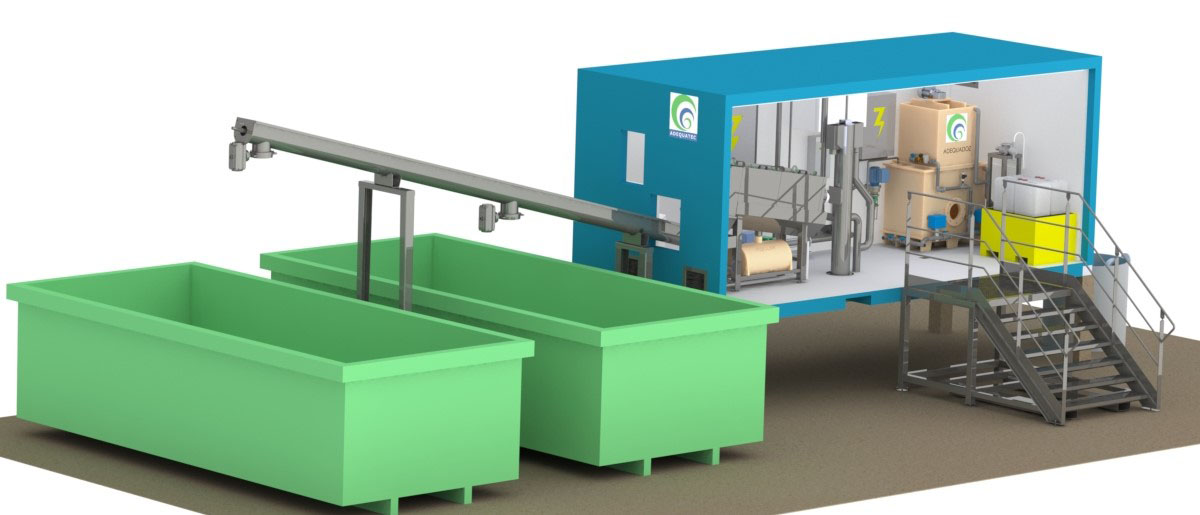

Mobile units

We offer mobile or containerized units with low energy consumption,

with capacities between 20 and 300 kg MS/h.

Adequapress ® : 3 ranges of screw presses for sludge dewatering and/or thickening

Adequapress New Generation : Since 2017, the ADEQUAPRESS screw presses are equipped with

Plug and Play drums. Just like a refillable filter cartridge, these new drums are replaced by new

are replaced by new drums during the five-yearly maintenance intervals. The

used drums are regenerated and put back into service. They do not generate any waste since 70% of their material is

of their material is reused and the remaining 30% is sent to a stainless steel recycling facility.

Adequapress DH Dehydration

Dryness :

16 à 35%

Capacity/Unit :

5 à 300 kg ms/h

Adequapress TH Thickening

Dryness:

5 à 11%

Capacity/Unit :

2 à 100 m3/h

Hybrid range Dehydration or thickening

Dryness:

5 à 35%

Capacité/U :

up to 160 kg ms/h / 60m3/h

Adequadoz ® :A range of automatic polymer preparation units

Sludge dewatering is a complex process composed of several successive steps, each one depending on the one that precedes it: flocculation, dewatering, thickening and finally pressing.

The flocculation stage requires a particular care which starts with the search for the best flocculant and its optimal dose: the treatment rate expressed in kg/ton of MS. Jars tests or pilot tests are used for this purpose.

The implementation of flocculation depends on the flocculation reactor and the preparation of the polymer.

The polymers used for sludge conditioning are supplied as a powder to be dissolved in water or as a concentrated solution to be diluted. In both cases, they must be mixed with water and then left to mature. This is done in two stages: a relatively short stage of intense mixing followed by a longer stage with gentle agitation to promote the growth of polymer chains.

The automatic polymer preparation unit ADEQUADOZ ® designed according to the rules of the art by ADEQUATEC responds perfectly to this problem. It is composed of two tanks: A preparation/maturation tank composed of two zones, each with a specific power adapted to mixing or maturation. A filling tank periodically fed with a diluted and matured polymer solution. The preparation is poured into this tank by gravity through an automatic valve. The operation of the plant is automated by means of a set of level sensors.

ADEQUAFLOOR® : An ultra-resistant monolithic filtering floor without formwork

ADEQUAFLOOR ® is a monolithic filtering floor that is very resistant (lifting pressure

(lifting pressure higher than 1 bar), easy to install (without cranes) and can be used for new or rehabilitated

open filters or in rehabilitation.